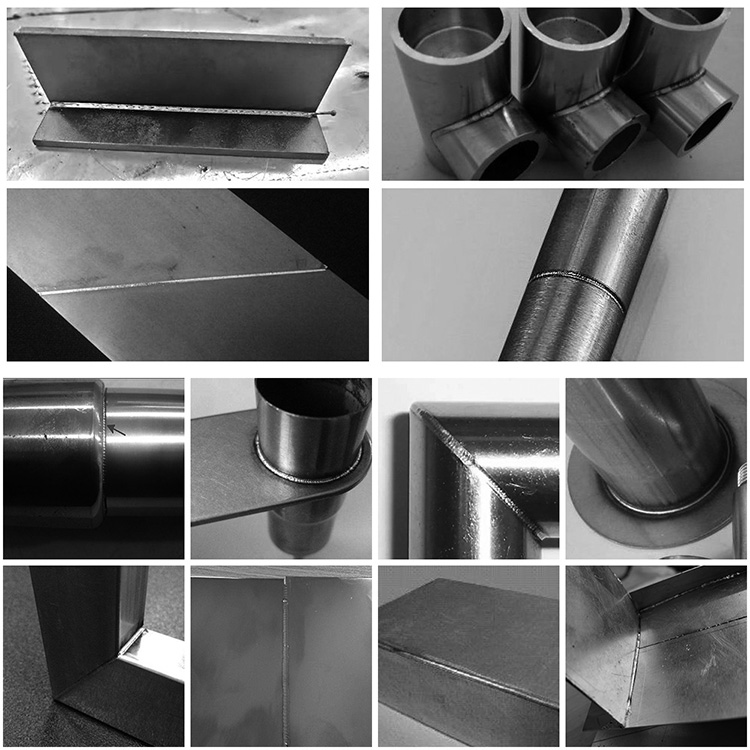

Mochini oa tjheseletsa oa Laser ke o mong oa mechini e sebelisoang tšimong ea tjheseletsa, 'me ke e' ngoe ea lintlha tsa bohlokoa tsa ts'ebeliso ea

theknoloji ea laser material processing.Mechini ea welding, joalo-joalo, joale ke indasteri efe e ka sebelisoang mochini oa welding oa laser?Tse nne ke tsena

liindasteri tsa lisebelisoa tsa mochini oa welding oa laser.

Lisebelisoa tsa tlhahiso

Mechini ea welding ea Laser e sebelisoa haholo indastering ea likoloi lapeng le kantle ho naha.Nakong e fetileng, mechine ea welding laser ea CO2 e ne e sebelisoa

Japane ho e-na le ho tjheseletsa ha flash butt ho hokahanya likhoele tsa tšepe tsa indasteri.Boithutong ba ho cheselletsa poleiti ea ultra-thin, mohlala,

li-foil tse nang le botenya ba li-micron tse ka tlase ho 100 li ke ke tsa chesetsoa, empa LAG laser welding e nang le li-waveforms tse khethehileng tse hlahisoang Katleho, welding ea laser.

bokamosong bo pharaletseng

Tšimo ea phofo ea metallurgy

Ka tsoelo-pele e tsoelang pele ea saense le thekenoloji, mekhoa e mengata ea theknoloji ea indasteri e na le litlhoko tse khethehileng tsa thepa, le thepa

e entsoeng ka mahlale a khale ha e sa khona ho fihlela litlhoko.Mochini oa welding oa laser o kene tšimong ea ho sebetsa ea

lisebelisoa tsa phofo ea metallurgy, e tlisitseng litebello tse ncha tsa nts'etsopele ea ts'ebeliso ea lisebelisoa tsa phofo.Ka mohlala, taemane

e cheselitsoe ka lisebelisoa tsa phofo tsa metallurgy tse kopanyang mekhoa e tloaelehileng ea brazing.Ka lebaka la matla a tlase a tlamahano le sebaka se pharaletseng se anngoeng ke mocheso,

haholo-holo haeba e sitoa ho ikamahanya le mocheso o phahameng le litlhoko tse phahameng tsa matla, e tla etsa hore solder e qhibilihe ebe e oa.Ho sebelisa laser

mochini tjheseletsa ka ntlafatsa tjheseletsa matla le ho hanyetsa mocheso phahameng.

Indasteri ea elektronike

Mechini ea welding ea laser e sebelisoa haholo indastering ea lisebelisoa tsa elektroniki.Ka lebaka la sebaka se senyenyane se anngoeng ke mocheso, mahloriso a futhumatsang ka potlako le a tlase

khatello ea maikutlo ea mocheso oa laser welding, melemo ea laser welding e bontšoa ka har'a sephutheloana sa lipotoloho tse kopaneng le sesebelisoa sa semiconductor.

matlo, le welding laser e boetse e sebelisoa ho nts'etsopele ea lisebelisoa tsa vacuum.Kapa botenya ba rekere tšesaane-mabota masenke

poleiti ka thermostat ke 0.05-0.1mm, eo ho leng thata ho e rarolla ka mekhoa e tloaelehileng ea ho tjheseletsa.TIG welding e sebetsa hantle ebile e sebelisoa haholo ka lebaka

ho kenella habonolo ha tjheseletsa, botsitso bo fokolang ba plasma le lintlha tse ngata tse susumetsang..

Indasteri ea likoloi

Hajoale, mohala oa tlhahiso ea mochini oa welding oa laser o hlahile ka tekanyo e kholo indastering ea tlhahiso ea likoloi mme e fetohile e 'ngoe

ea likatleho tse babatsehang tsa indasteri ea tlhahiso ea likoloi.Baetsi ba likoloi ba bangata ba sebelisa mekhoa ea ho tjheseletsa le ho itšeha ka laser.Matla a phahameng

lisebelisoa tsa tšepe tsa laser-welded li ntse li sebelisoa ka ho eketsehileng ha ho etsoa 'mele ea likoloi ka lebaka la thepa ea tsona e babatsehang.Ka lebaka la molumo o moholo

le boemo bo phahameng ba boiketsetso indastering ea likoloi, lisebelisoa tsa welding tsa laser li tla nts'etsapele ka lehlakoreng la matla a phahameng le ho etsa li-multiplexing.

Nako ea poso: Sep-28-2022